Cantek MX370M Automatic Edgebander (3PH)

Cantek MX370M Automatic Edgebander (3PH)

$28,200 (USD)

Description

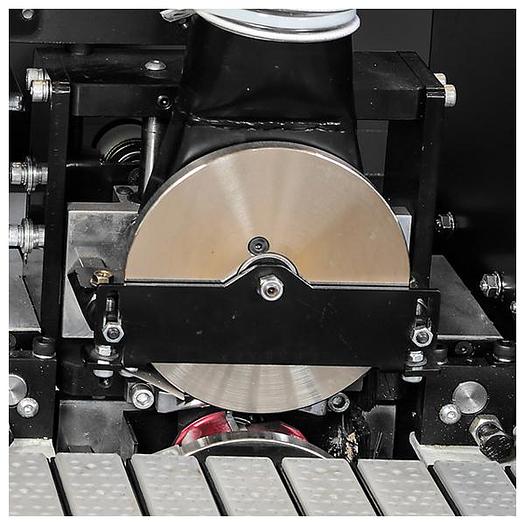

Pre-milling & corner rounding in a small footprint. The Cantek MX370M Edgebander is designed to be a compact & durable entry level edgebander with pre-milling & corner rounding functions offered at an affordable price. This machine is equipped with pre-milling, combination end trimming & corner rounding unit, flush trimming, PVC scraping, and buffing. User friendly controls and adjustments allow for efficient changeovers of edge tape thicknesses between 0.4mm & 3mm Why Cantek MX370M Edgebander? Compact design with dual function end trim and corner rounding unit Versatile edgebander capable of applying 0.4mm to 3mm edge tape Counter rotating diamond pre-milling heads ensure a perfectly square edge and clean panel to work with, resulting in a minimally visible glue joint The corner rounding function finishes the ends of cabinet doors and more with a radius edge, eliminating any manual rework of the panel Key Advantanges Automatic edge feeding with a thickness capacity of 0.4–3 mm; strip material can be hand-fed Conveyor chain feed system for reliable results with a feed speed of 23 FPM Heavy-duty pressure beam with extendable workpiece support Heated infeed fence for pre-heating the panel for optimum glue penetration Spring-loaded pressure unit with (2) pressure rollers Teflon-coated hot-melt glue pot User friendly 7” touch screen to control all edgebander functions Edge coil support plate for PVC/ABS coiled edgebanding Radius scraping and buffing units ensure a clean and vibrant edge Working Units TOUCH SCREEN INTERFACE Glue temperature settings Units can be selected and disengaged individually Heated fence is standard Keeps track of workpiece length, number or work pieces and hours. PREMILLING UNIT (2) diamond milling heads which are counter rotating mill the edge of the panel prior to applying the edgebanding for precise squareness and optimum edge results. Maximum removal of 3mm. END TRIM / CORNER ROUNDING UNIT Dual purpose unit for performing end trimming and corner rounding functions in one. Can flush trim or radius trim depending on the work piece being machined. FLUSH TRIMMING UNIT The standard copy roller disc for flush trimming unit is accurate, does not damage the work piece, and produces an optimum finish. Adjust cutter position with mechanical digital readout for straight or radius profile RADIUS SCRAPING Radius scraper with 2mm radius. BUFFING The buffing unit leaves a super finish on ABS and PVC edging, and removes any discoloration on the edges, which is especially noticeable when working with dark edge material. Specifications MOTOR POWER: WATCH VIDEO CANTEK MX370M

Specifications

| Manufacturer | Cantek |

| Condition | New |

| INCH | METRIC |

| Feeding speed | 7 m/min. 23 FPM |

| Panel thickness | 12~45 mm 0.472~1.77” |

| Edge thickness | 0.4 ~ 3 mm 0.0158”~0.118” |

| Minimum panel width | 90mm 3.54” |

| Minimum panel length | 170mm 6.7” |

| Min panel length w/ corner roundingWith panel height 12-30mmWith panel height 30-45mm | 170mm220mm 6.7″8.67″ |

| Working table height | 856mm 33.7” |

| Extensible support width | 560mm 22” |

| Extraction connection | 100mm x 3 4” x 3 |

| Pre-milling spindle speed | 12000 RPM |

| Top & bottom trimmer RPM | 10500 RPM |

| End trim/corner rounding RPM | 12000 RPM |

| Buffing RPM | 2800 RPM |

| Max. machine dimensions (LxWXH) | 3300x1200x1200mm 130” x 47 ¼” x 47 ¼” |

| Machine weight | 485 kgs 1067 lbs |

| Shipping dimensions (LxWxH) | 2920x720x1320mm 109” x 28 ½” x 54” |

| Shipping weight | 685 kgs 1507 lbs |

| Feed motor | 0.75 kW 1 HP |

| Pre-milling motor | 1.5 kW 2 HP |

| Glue spindle motor | 0.25 kW 1/3 HP |

| End trim/corner rounding motor | 0.35 kW ½ HP |

| Top & bottom trimming motor | 0.55 kW ¾ HP |

| Buffing motors | 0.12 kW x 2 0.16 HP x 2 |

| Heated infeed fence | 0.4 kW ½ HP |

| Total connected power | 5.47 kW 8 HP |