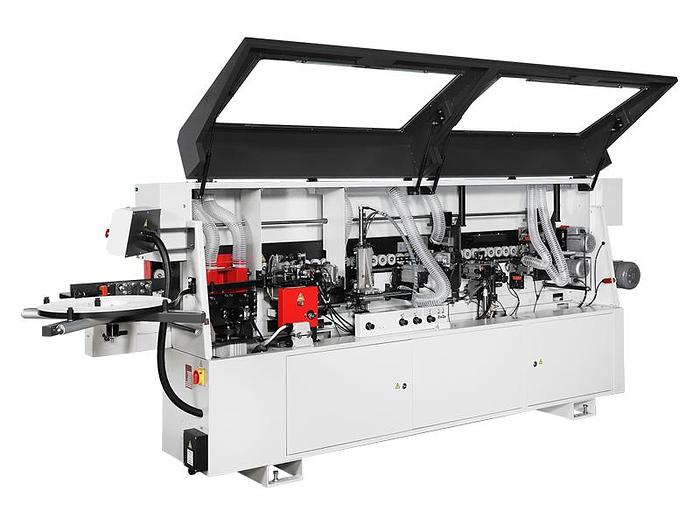

Cantek MX370PW Automatic Edgebander (3PH)

Cantek MX370PW Automatic Edgebander (3PH)

$38,500 (USD)

or

Call 239-770-4474

Description

CANTEK | MX370PW EDGEBANDER

From cabinet parts to cabinet doors, this edgebander can do it all.

The Cantek MX370PW Edgebander with Premilling and Corner Rounding is designed to be a compact and durable edgebander offered at an affordable price. This machine is equipped with premilling, end trimming, flush trimming, corner rounding, PVC scraping, and buffing. User-friendly controls and adjustments allow for efficient changeovers of edge tape thicknesses between 0.4mm & 3mm. It comes equipped with a strip feed magazine for automatically feeding of strips including wood, laminate etc.

WATCH VIDEO ON CANTEK MX370PW

Why Cantek MX370PW Edgebander?

Automatic strip feed magazine with up to 6mm edge capacity

Versatile edgebander capable of applying 0.4mm to 3mm edge tape.

Quick change glue pot allows you to change glue colours in minutes.

Premilling ensures a perfectly square edge and clean panel to work with, resulting in a minimally visible glue joint.

The corner rounding function finishes the ends of cabinet doors with a radius edge, eliminating any manual rework of the panel.

Key Advantages

Automatic edge feeding with a thickness capacity of 0.4–3 mm

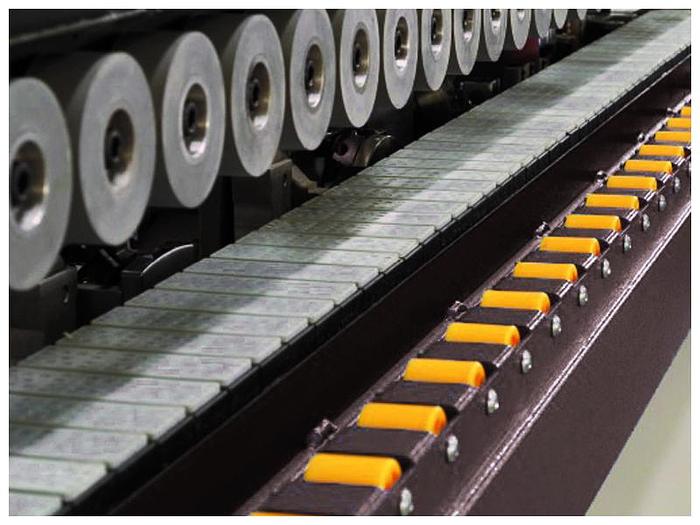

Conveyor chain feed system for reliable results.

Teflon-coated hot-melt glue pot.

Heated infeed fence for pre-heating the panel for optimum glue penetration.

PLC control system with LED display and keypad.

Workpiece is fed by chain.

Spring-loaded pressure unit with (2) pressure rollers.

Heavy-duty pressure beam with extendable workpiece support.

Working Units

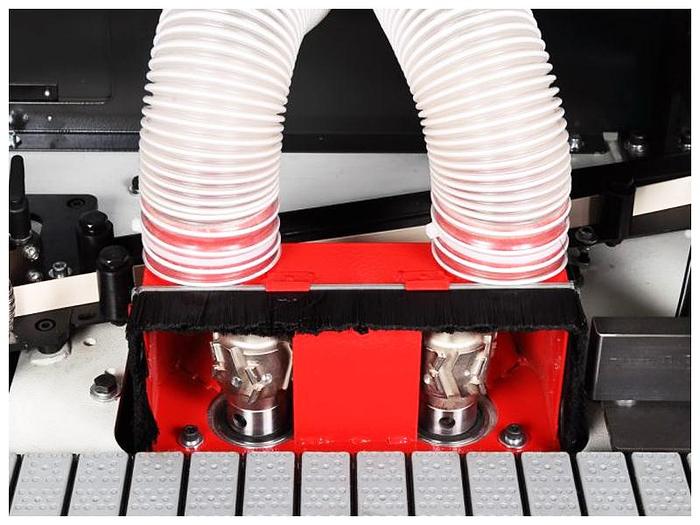

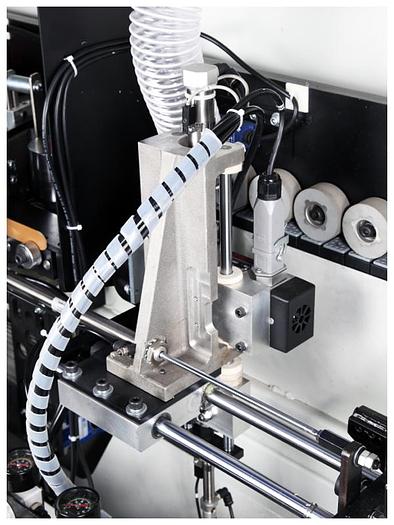

PREMILLING UNIT

High-frequency pre-milling units can remove up to 3mm and are designed to provide an ideal edge for applying edge tape by cleaning up poorly cut panels.

(2) counter-rotating diamond cutterheads for optimum results and longevity.

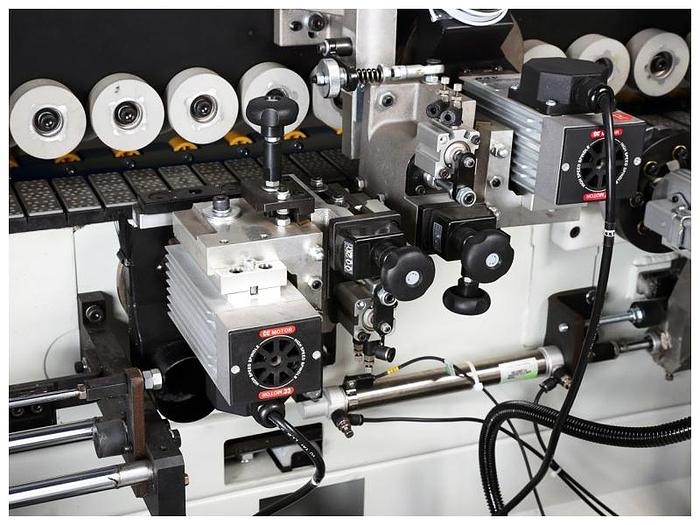

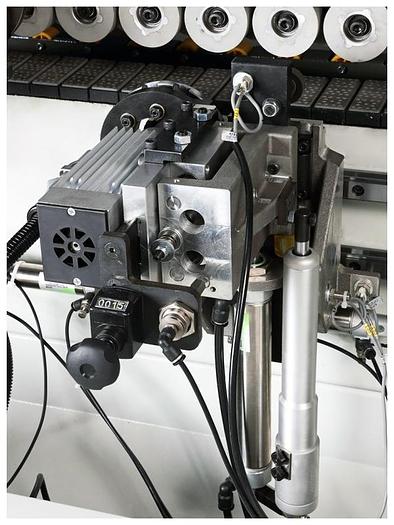

END TRIM

High frequency 12000 RPM end trimming unit, with Ø100mm (4”) TC-Saw blades.

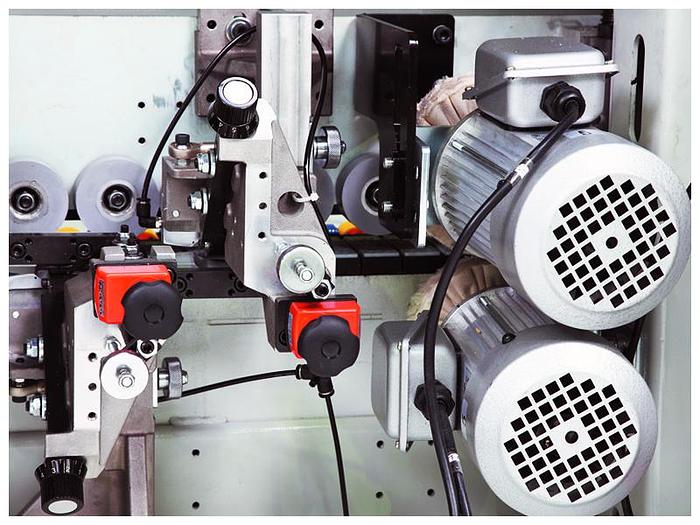

TOP & BOTTOM TRIM

High frequency 12000 RPM top & bottom trimmers with insert knife cutters for radius trimming & bevel trimming.

CORNER ROUNDING

High-frequency corner rounding unit can process 0.4-3mm thick edgebanding by tracing the shape of the panel.

RADIUS SCRAPING

Radius scraper with 2mm radius.

BUFFING

3000 RPM top & bottom buffing units to polish the machined edge.

Specifications

Motor Specifications

Specifications

| Manufacturer | Cantek |

| Condition | New |

| Feeding speed | 9 meters/min. 29 FPM |

| Panel thickness | 8~60 mm (coil)8~50mm (strip) 0.315″ ~2.36″ (coil)0.315”~2” (strip) |

| Edge thickness – coil | 0.4 ~ 3 mm 0.0158”~0.118” |

| Edge thickness – strips | to 6 mm to 0.24” |

| Min. panel width | 95 mm 3 ¾” |

| Min. panel length | 170 mm 6.7″ |

| Working table height | 960 mm 38″ |

| Extension support width | 560 mm 22″ |

| Dust collection outlet | Ø 127 mm x3 Ø 5″ x3 |

| Air consumption | 350 liters/min 12.36 CFM |

| Electrical consumption | 6.7 KW 10.9 HP |

| Electrical requirement | 26 Full load amps 230/3/60 |

| Machine weight | 980 kgs 2160 lbs |

| Machine dimensions | 3960 x 730 x 1748mm 156” x 29” x 69” |

| Feeding motor | 0.75 kW |

| Pre-milling motors (2 pcs) | 1.5 kW |

| Glue spindle motor | 0.25 kW |

| Front/rear trimming motor | 0.37 kW (12000 RPM) |

| Upper trimming motor | 0.37 kW (12000 RPM) |

| Lower trimming motor | 0.37 kW (12000 RPM) |

| Corner rounding motor | 0.35 kW (12000 RPM) |

| Upper buffing motor | 0.12 kW (3000 RPM) |

| Lower buffing motor | 0.12 kW (3000 RPM) |

| Pre-heating | 0.125 kW |

| Gluepot | 1.315 kW |

| Edge coil support plate | Ø 800mm (31 ½”) for PVC/ABS. |