CANTEK | SR1300NDA 52″ PLANER SANDER

CANTEK | SR1300NDA 52″ PLANER SANDER

$92,000 (USD)

Description

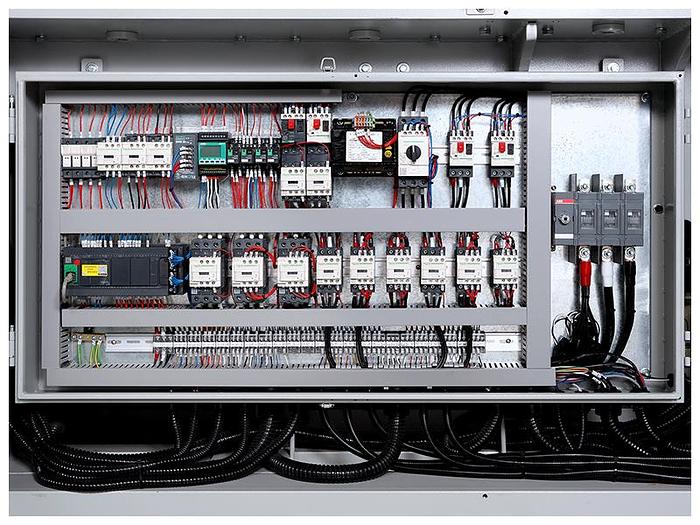

High-production planer sander greatly reduces the number of passes, increasing your productivity. The Cantek SR1300NDA 52” Planer Sander is designed to greatly increase your efficiency when planning and sanding solid wood components. The spiral insert knife cutterhead produces a fine finish and requires less horsepower than traditional straight knives. When one cutting edge becomes dull you simply slide the head assembly out of the machine and rotate the knives to a fresh edge. The SRN series incorporates an extra heavy-duty frame, industrial cast-iron pressure shoes, and cast-iron sanding head assemblies. These features allow the SRN series to excel in high-production environments and demanding widebelt sanding applications. Why Cantek SR1300NDA 52″ Planer Sander? Heavy-duty construction for production use. Powerful horsepower for efficient stock removal, calibration, and final sanding. Planer head followed by two sanding heads to increase throughput by minimizing grit changeovers. Spiral insert knife planer cutterhead for superior stock removal with unparalleled finish quality. Solid cast iron sanding heads and mounting base for superior vibration damping resulting in an optimal sanding result. User-friendly touchscreen control adjusts the feed speed, thickness setting, motor power and more. Variable feed speed adjustment. Independent motors for each sanding unit. “N” planer unit = 7” diameter cutterhead with replaceable insert knives in a spiral pattern requiring less horsepower while providing superior planed finish prior to sanding operations. “D” sanding unit = 10” diameter contact drum available in Steel or Rubber. Key Advantages Versatile configuration with spiral insert knife cutterhead followed but a rubber contact drum and then a combination sanding unit with rubber drum and adjustable platen. Electronic belt tracking for optimum belt life and sanding results. Powerful air jet belt cleaning units remove dust build-up on sanding heads for better sanding results and promote longer belt life. Clear plastic windows allow the operator visual access to the sanding heads to ensure proper oscillation and observation of the sanding belts without having to open and shut down the machine. Heavy-duty fixed base with dual rubber pressure rollers between sanding heads. Amp meter for load monitoring to ensure the proper amount of material is removed according to selected abrasive belt grit. Pressure hold-down system consists of sectional infeed pressure shoe before the cutterhead, and dual rubber pressure rollers between and after sanding head. Anti-kickback safety device before the cutterhead for added operator safety. High-quality Italian rubber conveyor with belt tracking. Extended infeed bed with two table rollers. The automatic maintenance system reminder feature will assist with notifications for maintenance. Two LED indicators: a blue light for normal operation and a red light that indicates error as an error. Allows you to monitor the sander at all times. Caliper thickness setting unit for fast setup to your workpiece. Disc brakes on the main motors to allow for faster belt changes and improved safety. Pneumatic belt tensioning with quick-release outboard support to facilitate fast belt changes. Four table raising jack screws. Material over-height limit switch on infeed will quickly shut down the machine should the operator feed material which is beyond the thickness setting of the machine. Safety interlock switches located on all access doors. Specifications

Specifications

| Manufacturer | CANTEK |

| Condition | New |

| Abrasive belt size | 1346 X 1905 mm 53” x 75” |

| 1st Main motor (Planer) | 40 HP |

| 2nd Main motor (Drum) | 25 HP |

| 3rd Main motor (Combi) | 20 HP |

| Feed motor | 5 HP |

| Table rise/fall motor | 1 HP |

| Working width | 1320 mm 52″ |

| Minimum part length | 430 mm 16.9″ |

| Maximum thickness opening | 120 mm 4.7″ |

| Feed speed variable | 4 to 18 m/min 13 to 59 FPM |

| Pass line height | 950 mm 37″ |

| Dust outlet | 11 @ 127 mm 11 @ 5” |

| Compressed air pressure | 6 Kg/cm2 PSI 85 |

| Compressed air volume | 0.5M3/Min 18 CFM |

| Dust collection requirements | 13,700 M3/HR 8,063 CFM |

| Net weight | 5000 kgs 11,023 lbs. |

| Machine dimensions | 2500 x 2100 x 2025 mm 98” X 82” X 79” |

| Shipping weight | 5,550 kgs 12,125 lbs. |

| Shipping dimensions | 2930 x 2030 x 2090 mm 115” X 79” X 82” |

| Electrical requirements | 460/3/60 |